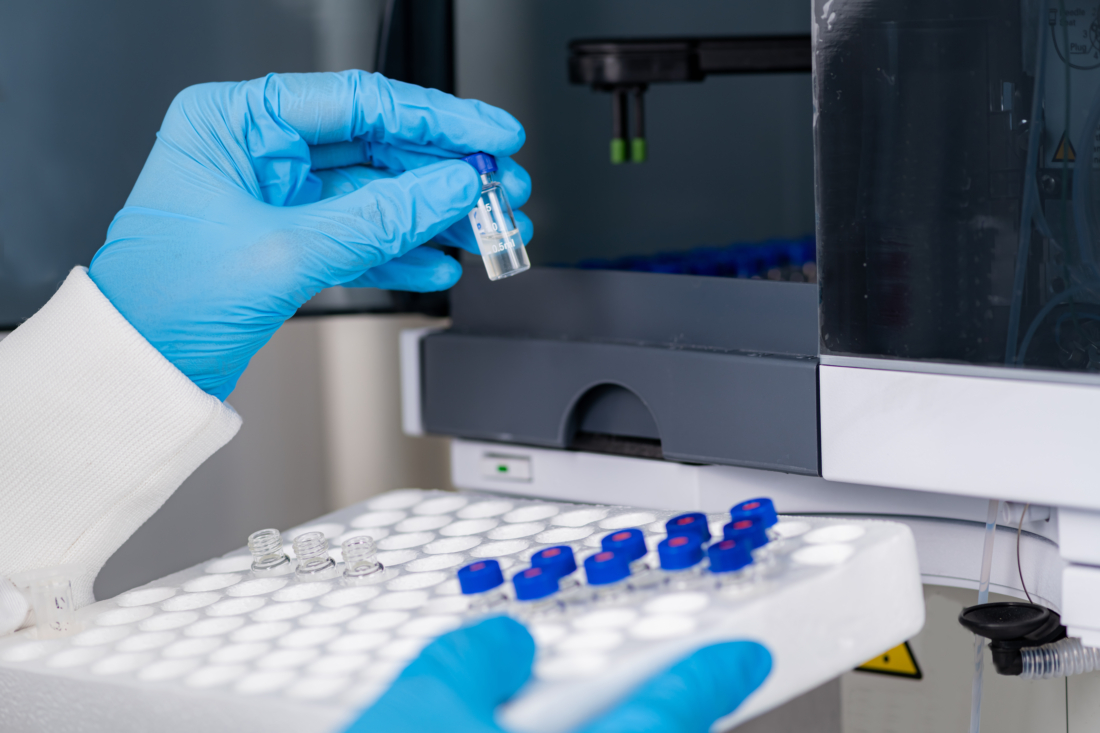

Within the Quality Control laboratories, it is essential to verify and control all products delivered to the health market. From pharmaceutical products to medical devices, including biotechnologies, it is imperative to implement these controls in order to guarantee the quality, effectiveness and safety of the products delivered.

Numerous standards and regulations govern the development of analytical methods and the commissioning of equipment. Whether for physico-chemical, microbiological or mechanical tests, it is imperative to qualify and validate all the analytical methods and equipment in order to be in control of your processes.

With our expertise and know-how, we are able to support you in the development of your methods, the management of your equipment qualifications while maintaining your quality level within the laboratory.

Our consultants are trained in the mastery of analytical techniques, Qualification / Validation tools and Lean management, which will allow you to maintain a level of excellence within your Quality Control laboratory.

We accompany all your projects related to quality control on :

According to regulatory standards: GLP, ISO 17025, ICH and pharmacopoeia

A strategic accompaniment is set up on your various subjects