Challenges in Qualification / Validation in Pharma & MD industry

Medical Device and Pharmaceutical industry encounter challenges in Qualification / Validation (QV)

The healthcare industry is constantly faced with product quality, hygiene, environmental and safety issues, as well as regulatory issues and business risks.

Alispharm works with its clients to help them secure their industrial environment, from the design phase to the marketing of their products.

The Qualification/Validation process takes on its full meaning in this industrial environment control perspective. Our QV engineers work with our clients to help them proactively meet the regulatory requirements in force by securing and controlling all production processes and materials in order to guarantee the quality and hygiene of the products and the company’s performance.

Qualification processes

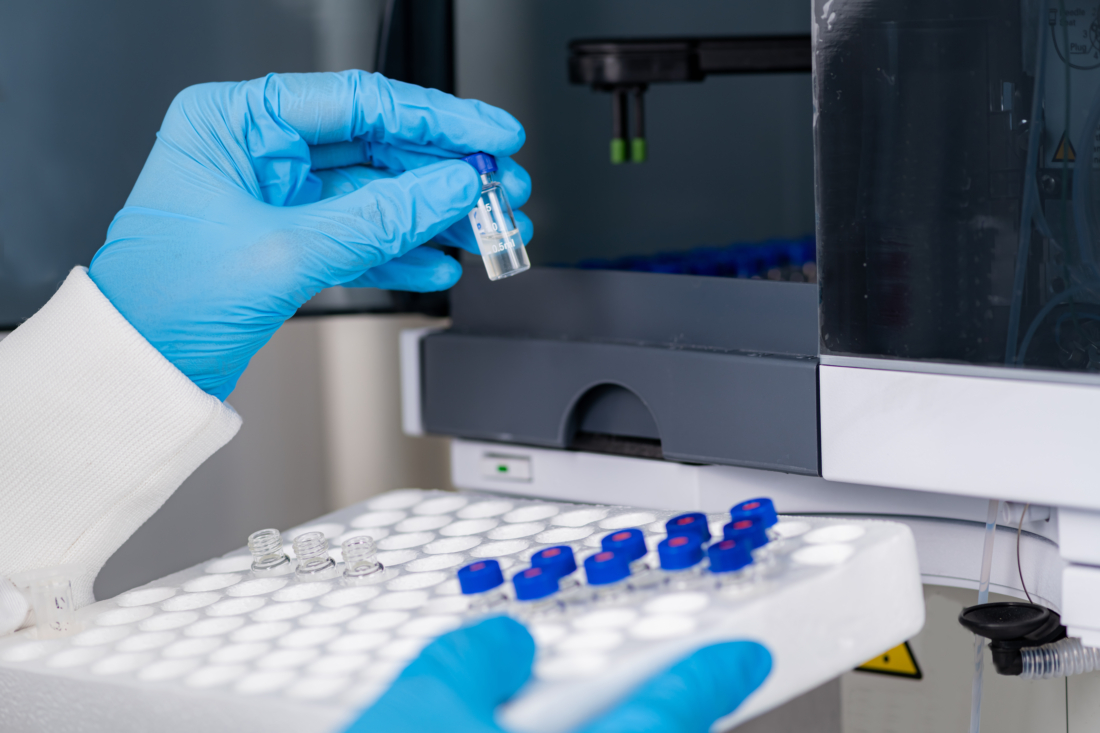

In order to ensure the conformity of all the equipment used by our industrialists, our QV experts intervene on Qualification processes. Equipment such as packaging lines, tablet presses or even all laboratory equipment such as BacSpot Reader, incubators or climatic chambers are qualified. Our engineers ensure the proper installation of each piece of equipment (Installation Qualification) and the concordance of the results/products obtained with the specifications predefined in the URS and the Specifications (Operational Qualification / Performance Qualification). The premises, distribution networks and air treatment systems associated with each piece of equipment will also be monitored in this Qualification process.

Validation

In parallel, our experts also work in Validation in order to secure and control all the production processes and methods used, always with the objective of guaranteeing the quality of the products and results. Thus, each manufacturing process (e.g. drying process, compression process), packaging, cleaning and storage process will be deployed to control their conformity. Computerized systems are also monitored as part of this Validation process.

What we do in Qualification / Validation

Alispharm offers its services from the elaboration of the QV strategy and by proposing the drafting of risk analyses, test protocols and thus the deployment of the strategy, the execution of the tests and the analysis of the results. As Qualification/Validation is an integral part of the Quality process of our industrialists, Alispharm ensures that it accompanies them with rigor in order to best respond to the challenges and problems of the industrial health environment.

Challenges in Qualification / Validation

- Stringent Regulatory Requirements: The medical device and pharmaceutical industries are highly regulated. Meeting and staying compliant with ever-evolving regulatory standards, such as those from the FDA or other health authorities, can be a significant challenge.

- Complexity of Processes: Manufacturing processes in these industries are often intricate and involve multiple steps. Ensuring the qualification and validation of each step, from raw material sourcing to the final product, can be complex and time-consuming.

- Diverse Equipment Qualification: Qualifying a wide range of equipment, from manufacturing machinery to laboratory instruments, adds complexity. Each piece of equipment needs to be installed correctly, and its performance must align with predefined specifications.

- Data Integrity and Documentation: Maintaining accurate and reliable data throughout the QV process is crucial. Challenges may arise in ensuring data integrity, proper documentation, and traceability of results back to the initial specifications.

- Changing Technology: The introduction of new technologies, automation, and computerized systems poses challenges in terms of validation. Ensuring the compliance and reliability of these systems is a continual process.

- Globalization and Supply Chain Issues: With global supply chains, ensuring the qualification and validation of raw materials, components, and processes across different geographical locations can be challenging. Variability in suppliers and supply chain disruptions may also impact the QV process.

- Personnel Training and Competency: Adequate training and competency of personnel involved in the QV processes are essential. Ensuring that the team understands and follows established protocols is crucial for the success of qualification and validation efforts.

- Risk Management: Conducting thorough risk analyses and addressing potential risks in the QV process is a continuous challenge. Anticipating and mitigating risks to product quality and patient safety is paramount.

- Adaptation to Industry Advances: Staying abreast of industry advancements and integrating new technologies or methodologies into existing QV processes can be challenging. Balancing innovation with the need for proven and validated methods is crucial.

- Time and Cost Pressures: There is often pressure to complete the QV processes efficiently and cost-effectively without compromising on quality. Striking the right balance between speed and thoroughness is an ongoing challenge.